hummingbirds, has a strong focus on Nature-based Solutions (NbS), but we also work on Efficient Cooking Solution projects, also known as Improved Cookstove (ICS) projects.

These projects are designed to reduce carbon emissions by increasing the cooking efficiency, consequently decreasing the quantity of fuel needed, in particular woody biomass.

Traditional cooking methods, notably three-stone fire, release a large quantity of toxic pollutants that pose serious health risks, especially to women. They also consume a lot of fuelwoods, which results in forest degradation and deforestation.

By replacing these traditional methods with more efficient cookstoves, we can significantly reduce emissions, improve air quality and reduce respiratory diseases, save time for women and children, and allow them to pursue education and economic activities.

There are two main types of cookstove projects in the Voluntary Carbon Market (VCM):

Among these, Improved Efficiency Cookstoves are the most common in the VCM. Currently, there are more than 1,800 registered projects across different standards, with over 113 million carbon credits issued.

Simply put, the emission reductions in cookstove projects are determined by comparing the amount of fuel used before and after the introduction of improved cookstoves. This calculation follows a methodology that ensures accuracy and transparency in measuring carbon savings. Some of the methodologies currently available are the Reduced emissions from cooking and heating – Technologies and Practices to displace Decentralised Thermal Energy Consumption (TPDDTEC) from Gold Standard and VM0050 Energy Efficiency and Fuel-Switch Measures in Cookstoves, v1.0 from the VCS standard.

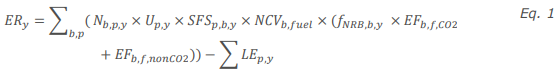

If we see the equation used to calculate the total emission reductions for a cookstove project, it might look quite complex:

Source: Gold Standard TPDDTEC methodology

Therefore, understanding the parameters that estimate the total GHG emissions avoided is very important. Overall, the following factors are considered:

The key goal of ICS projects is to reduce the amount of biomass required for cooking. Fuel savings can be measured in two ways:

The total number of cookstoves distributed and the date when each cookstove starts to be operational are very important factors, as they will multiply the total amount of wood savings daily.

The total usage rate is the percentage of households actively using the improved cookstove. There are two main methods to estimate this number:

Not all biomass is renewable. The fNRB parameter estimates the percentage of harvested wood that exceeds natural regeneration rates, meaning it contributes to deforestation/forest degradation.

This parameter can be estimated either using models such as MOFUSS or using the default value of 0.3 (30%) provided by the Clean Development Mechanism (CDM).

At hummingbirds, we use the most up-to-date values from MOFUSS, a GIS-based dynamic model that simulates fuelwood harvesting impacts across landscapes. This ensures a more precise and conservative calculation of non-renewable biomass usage.

Each type of fuel has a specific emission factor—a default value representing the amount of GHG released per unit of energy. The emission factors are provided by carbon methodologies, ensuring consistency across projects.

NCV represents the energy content per unit of fuel. Each type of biomass has a specific NCV, which influences the amount of fuel required for cooking. This parameter is also a default value provided by methodologies.

Leakage is calculated by assessing whether the reduced fuel consumption in project households leads to increased fuel use elsewhere.

Accurate carbon calculations ensure that cookstove projects:

Cookstove projects are a powerful tool in the fight against climate change, forest degradation and air pollution. By improving fuel efficiency and reducing emissions, they protect both people and the planet.

At hummingbirds, we are committed to ensuring that every carbon credit generated truly reflects a reduction in emissions,. In our improved cookstove projects, we follow the latest Core Carbon Principles guidelines published by the Integrity Council for the Voluntary Carbon Market (ICVCM), including using the fNRB provided by the MOFUSS model, developing appropriate KPT tests, and ensuring good monitoring practices such as the use of SUMs.

An example of this is our Bissap project, which aims to deploy 150,000 improved stoves in Benin, positively impacting women’s livelihoods, creating around 40 full-time jobs and reducing indoor pollution.

As we continue to innovate, hummingbirds remains dedicated to delivering real impact—ensuring that carbon savings are measurable, transparent, and scientifically robust.